Premium Quality Sliding Bushing

| Manufacturer | DALON |

| Material | COMPOSITE MULTILAYER |

| Type | FLANGE BUSHING |

| Working Temperature | From -200°C to + 280°C |

| Product Code | DOB-1F |

| Density (g/cmÂł) | 7.5 |

| HS Code | 8483300090 |

| Hardness | >220 |

| Static Load (Mpa) | 250 |

| Max Speed (m/s) | 2.5 |

| Max PV (dry) | 1.8 |

| I.D.(d) | 10 |

| I.D. (d1) | |

| O.D. (D) | 12 |

| O.D. (D1) | |

| Length (L) | 1 |

| Flange Dia. (fd) | 18 |

| Flange Thickness (fl) | 9 |

| General Tolerance | F7 r7 js13 |

| Weight(ref)/Gram | 0.00 |

| Minimum Order Qty | 40KGS |

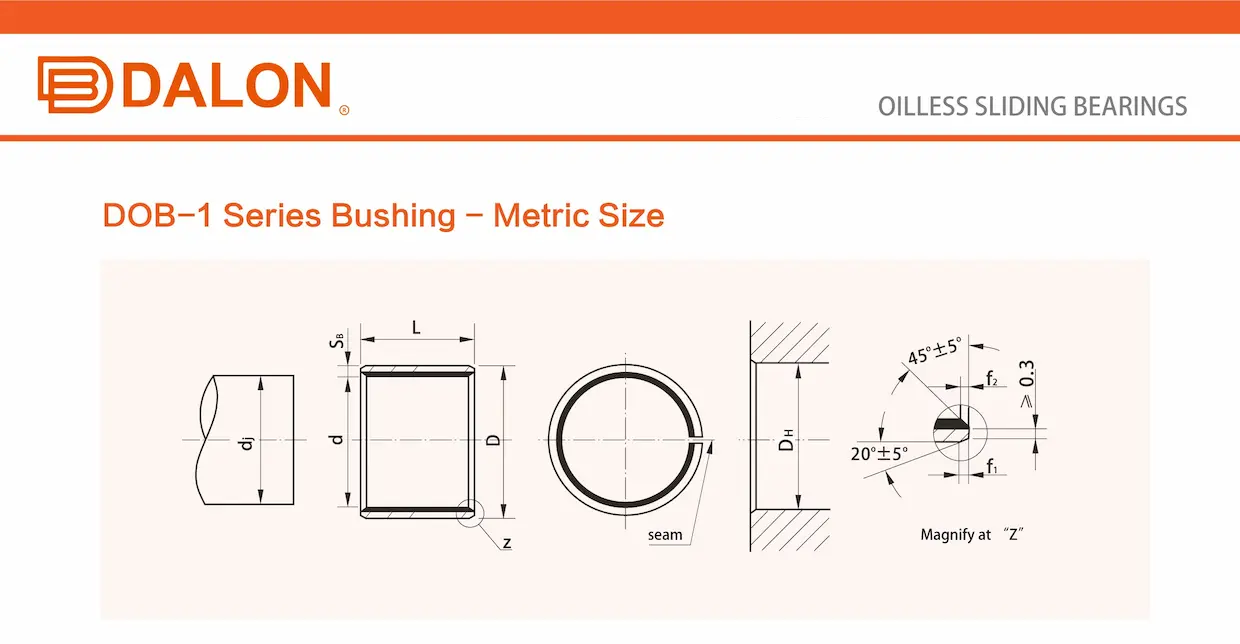

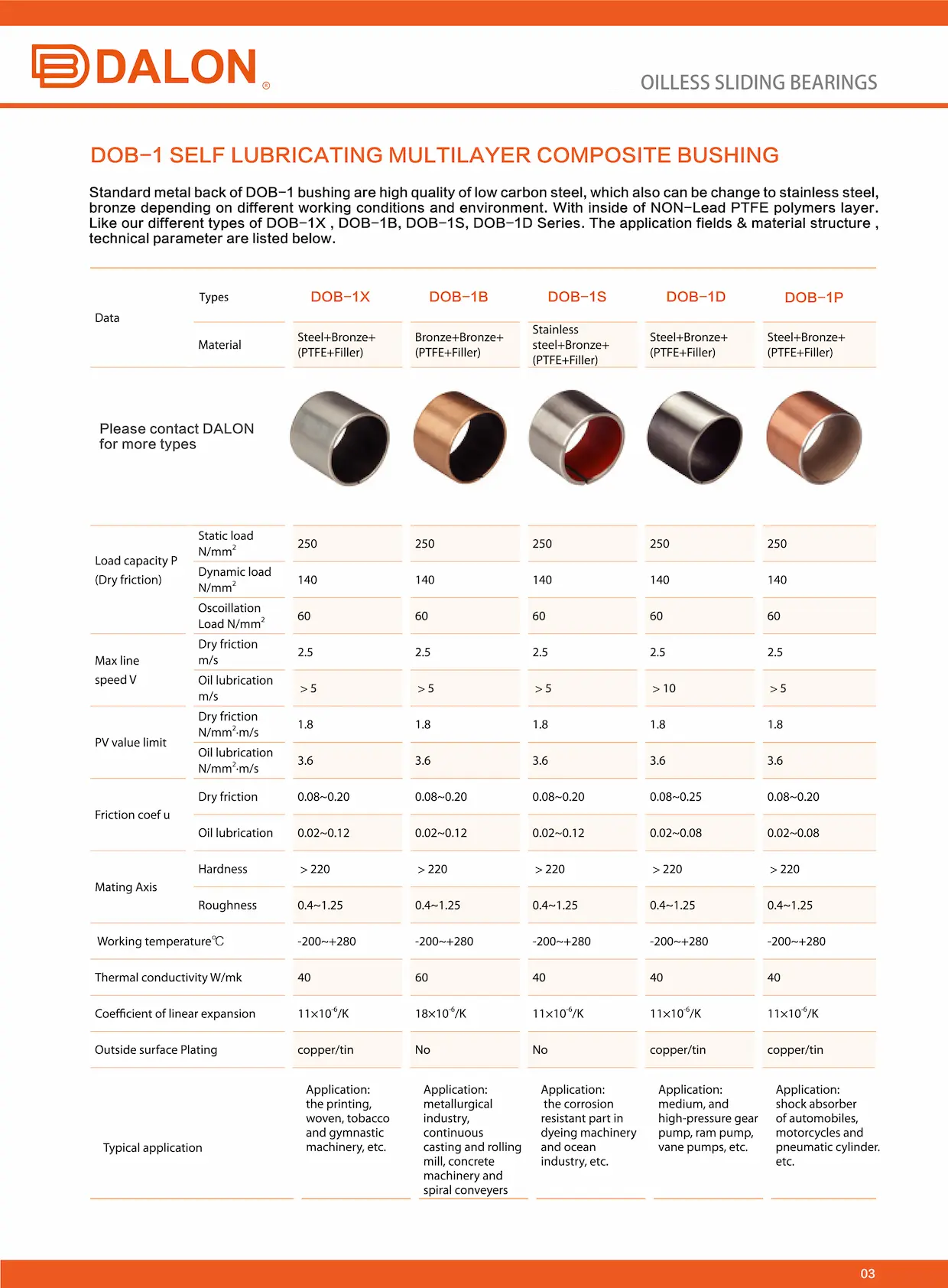

DALON’s Sliding Flange Bushing 10×12×18×1×9 is a precision-formed, self-lubricating bronze bearing designed for compact assemblies that require both radial support and axial positioning. Featuring a flanged construction, this bushing combines easy installation with reliable alignment, making it ideal for applications with space constraints and light to moderate loads.

The dimension format follows DALON’s standardized spec sequence:

ID: 10 mm

OD: 12 mm

Flange OD: 18 mm

Flange Thickness: 1 mm

Total Length: 9 mm

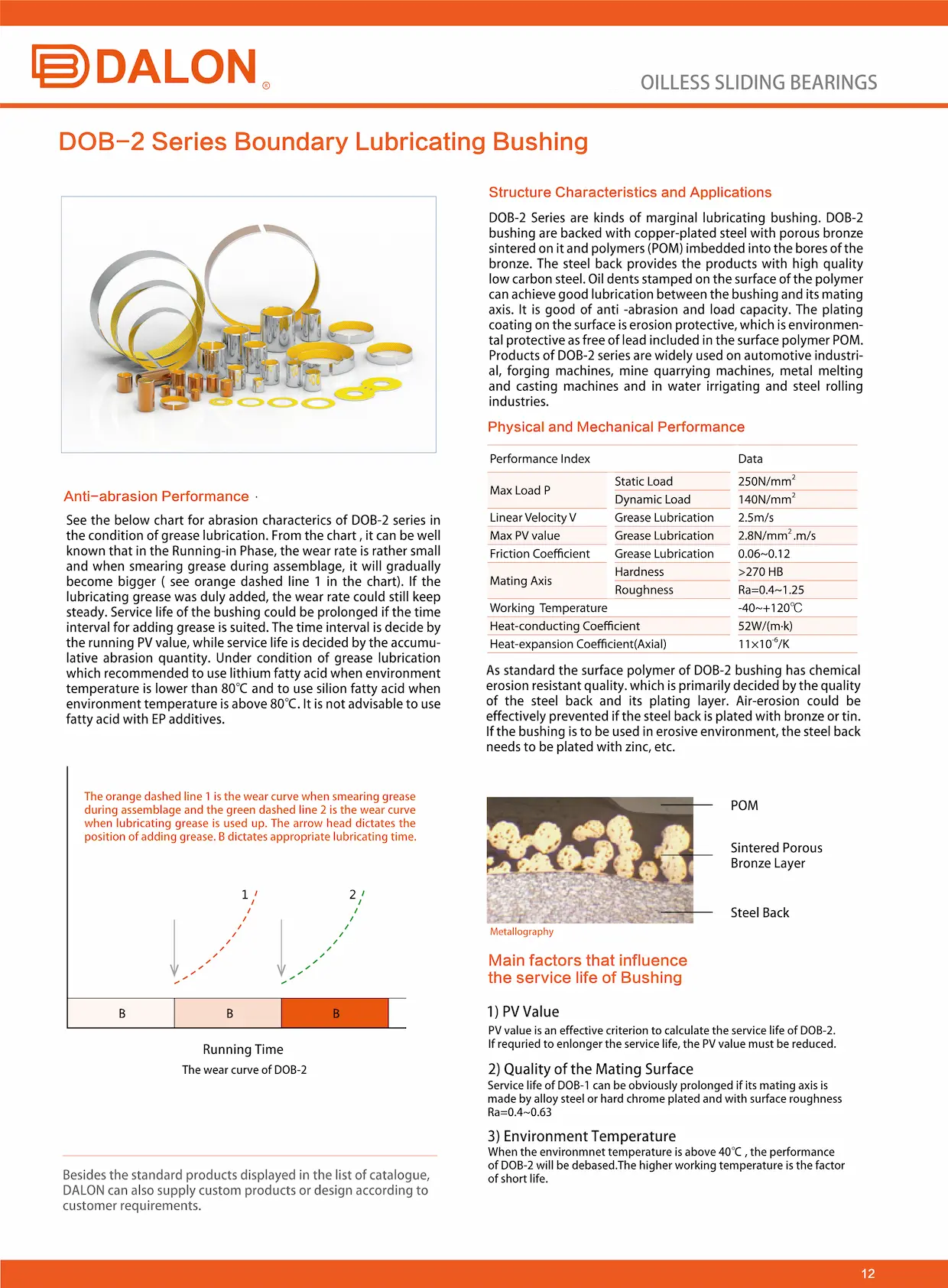

Manufactured from high-density sintered bronze or bronze alloy, the bushing offers excellent wear resistance, thermal stability, and dry-running performance. The flange ensures secure axial location without additional fasteners or retainers, making it suitable for press-fit or slip-fit housing assemblies.

Dimensions: 10×12×18×1×9 mm (ID × OD × Flange OD × Flange Thickness × Total Length)

Material: Bronze alloy (self-lubricating; graphite optional)

Operating Conditions:

Temp Range: –40°C to +250°C

Load: Up to 60 N/mm² dynamic

Speed: Suitable for moderate speeds

Installation: Easy press-fit into aluminum or steel housings

Design Type: Oilless sliding sleeve with axial flange retention

Servo motor pivots and linkages

Pneumatic and hydraulic control systems

Compact automation equipment

Linear actuator interfaces

Portable machinery and miniature gearboxes

Office and home appliance mechanisms

Tailored Engineering: Custom bushing size, flange style, and lubrication type available

Fast Lead Times:

Standard mold items: ~30 days

Custom bushing (with mold): 35–40 days

Material Versatility: Options include sintered bronze, graphite-impregnated types, or custom bronze alloys

ISO 9001:2015 Certified Production

Support for Prototyping to Mass Production

|

Question |

Answer |

|---|---|

|

Q1: What is this bushing used for? |

It provides a low-friction, durable support for rotating or sliding shafts in small mechanical systems. |

|

Q2: What does the flange do? |

The flange holds the bushing in place axially and simplifies installation without additional hardware. |

|

Q3: Can I use this without grease or oil? |

Yes. It’s designed for dry-running with self-lubricating properties. Optional graphite versions are available. |

|

Q4: What is the delivery time for custom bushings? |

Normally 35–40 days for new designs; existing mold parts can be delivered in ~30 days. |

|

Q5: What materials are available? |

Standard is bronze alloy; custom materials such as bronze + graphite or POM can be quoted upon request. |

|

Q6: What industries use these bushings? |

Used in robotics, automation, automotive interiors, HVAC actuators, and light-duty machinery. |

The self-lubricating properties of SLIDING FLANGE BUSHING 10X12X18X1X9 make them ideal for numerous applications, including:

SLIDING FLANGE BUSHING 10X12X18X1X9 are designed for environments where traditional lubrication is impractical or impossible. They offer outstanding performance, durability, and cost savings, making them the preferred choice for various industries. Experience the reliability and efficiency of SLIDING FLANGE BUSHING 10X12X18X1X9, tailored to meet the demands of your specific applications.

Our professional team is ready to assist with your inquiry for this Flanged Sliding Bushing – 10×12×18×1×9 Bronze Sleeve Bearing.

Contact UsAll our products are manufactured according to ISO 9001 standards.

View CertificatesWe offer free design services and custom manufacturing for your specific needs.

We provide worldwide shipping for all our products with reliable delivery times.