Premium Quality Sliding Bushing

| Manufacturer | DALON |

| Material | COMPOSITE MULTILAYER |

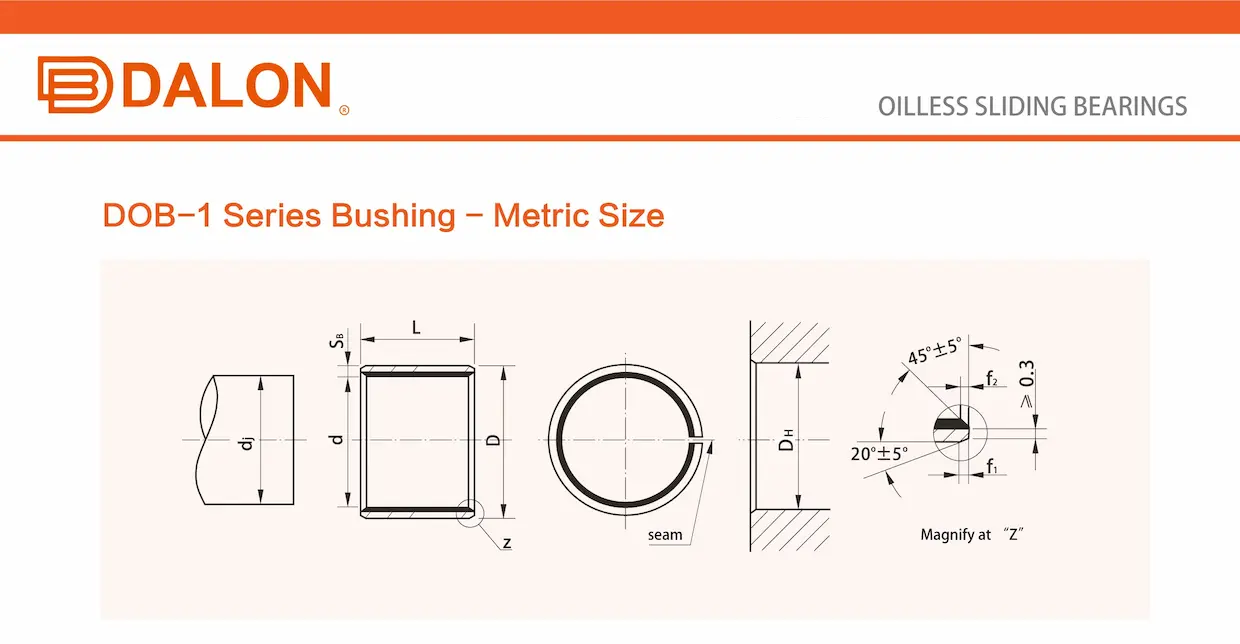

| Type | SLEEVE BUSHING |

| Working Temperature | From -200°C to + 280°C |

| Product Code | DOB-1 |

| Density (g/cmÂł) | 7.5 |

| HS Code | 8483300090 |

| Hardness | >220 |

| Static Load (Mpa) | 250 |

| Max Speed (m/s) | 2.5 |

| Max PV (dry) | 1.8 |

| I.D.(d) | 10 |

| I.D. (d1) | |

| O.D. (D) | 12 |

| O.D. (D1) | |

| Length (L) | 15 |

| Flange Dia. (fd) | |

| Flange Thickness (fl) | |

| General Tolerance | F7 r7 js13 |

| Weight(ref)/Gram | 0.00 |

| Minimum Order Qty | 40KGS |

DALON’s Sliding Sleeve Bushing 10×12×15 is a compact and reliable bronze sleeve bushing designed for dry-running or marginally lubricated mechanical systems. Manufactured using sintered powder metallurgy technology, this bushing features a porous bronze structure that is factory-impregnated with lubricating oil to ensure consistent, maintenance-free performance across a wide range of applications.

With an inner diameter of 10 mm, outer diameter of 12 mm, and length of 15 mm, this small-format bearing is ideal for precision motion components where space is limited, yet long service life and reduced friction are critical. Its tight dimensional tolerances ensure smooth shaft rotation, low noise, and minimal vibration.

Engineered from high-quality bronze, this sleeve bushing resists corrosion, performs reliably under varied temperatures, and is especially well-suited for intermittent or continuous motion in office equipment, small electric motors, automation assemblies, and consumer electronics.

Material: Sintered bronze with oil impregnation

Size: 10 mm ID × 12 mm OD × 15 mm Length

Self-lubricating: No additional oil or grease required during use

Space-saving design: Suitable for compact assemblies

Quiet performance: Reduces noise and mechanical vibration

Durable and corrosion-resistant: Ideal for dry or mildly corrosive environments

ISO 9001:2015 certified manufacturing

Electric motors and gearboxes

Office automation equipment

Consumer appliances

Robotics and linear motion assemblies

Packaging machinery

HVAC actuators and sensor systems

DALON offers precision-manufactured oilless sliding bushings using advanced sintering processes that create uniform porosity and long-lasting lubrication retention. Our bushings are designed for OEM integration across various industries requiring compact, quiet, and efficient rotary or sliding motion.

We provide:

Custom bushing dimensions, materials, and tolerances

Short tooling and production cycles for new designs

Standard product delivery in 30 days

Customized product delivery in 35–40 days, including mold development

Application-specific support for optimal design fit and performance

Whether you’re prototyping or scaling up, DALON helps reduce friction and extend machinery life with reliable bronze sleeve bushings.

Q1: What is the function of a bronze sleeve bushing?

It acts as a low-friction interface between a rotating shaft and housing, reducing wear and extending system life—especially when used without additional lubrication.

Q2: Can I use this bushing for vertical applications?

Yes. As long as radial and axial loads are within acceptable limits, this bushing is suitable for both vertical and horizontal installations.

Q3: Is this 10×12×15 bushing available in custom sizes?

Absolutely. DALON offers full customization including ID, OD, and length as well as material options tailored to your application’s demands.

Q4: What makes sintered bronze bushings different from machined ones?

Sintered bushings have internal porosity, allowing them to retain lubricant and operate without grease, while machined bushings typically require external lubrication.

Q5: What are the delivery times for standard vs. custom bushings?

Standard sizes ship in about 30 days. Customized sizes or new designs require 35–40 days including mold tooling and production.

Q6: What are the minimum order quantities for custom bushings?

It depends on the complexity of the design and size. Please contact DALON directly for MOQ and custom solution support.

Q: Are bronze bushings better than plastic ones?

For higher loads, temperature resistance, and longer service life, bronze bushings are generally more reliable than plastic alternatives.

Q: Can bronze bushings be reused?

Yes, if they are not excessively worn or damaged. Many can be cleaned and reinstalled if still within tolerance.

Q: Do self-lubricating bushings wear out?

Yes, like all mechanical parts, they eventually wear over time. However, their design ensures long intervals between replacements.

Q: How do I install a bronze sleeve bushing?

Press-fit installation is most common. Ensure proper alignment and use a tool that matches the outer diameter to avoid distortion.

The self-lubricating properties of SLIDING SLEEVE BUSHING 10X12X15 make them ideal for numerous applications, including:

SLIDING SLEEVE BUSHING 10X12X15 are designed for environments where traditional lubrication is impractical or impossible. They offer outstanding performance, durability, and cost savings, making them the preferred choice for various industries. Experience the reliability and efficiency of SLIDING SLEEVE BUSHING 10X12X15, tailored to meet the demands of your specific applications.

Our professional team is ready to assist with your inquiry for this DALON Bronze Sleeve Bushing – Precision Sliding Bushing 10×12×15.

Contact UsAll our products are manufactured according to ISO 9001 standards.

View CertificatesWe offer free design services and custom manufacturing for your specific needs.

We provide worldwide shipping for all our products with reliable delivery times.