Premium Quality Sliding Bushing

| Manufacturer | DALON |

| Material | COMPOSITE MULTILAYER |

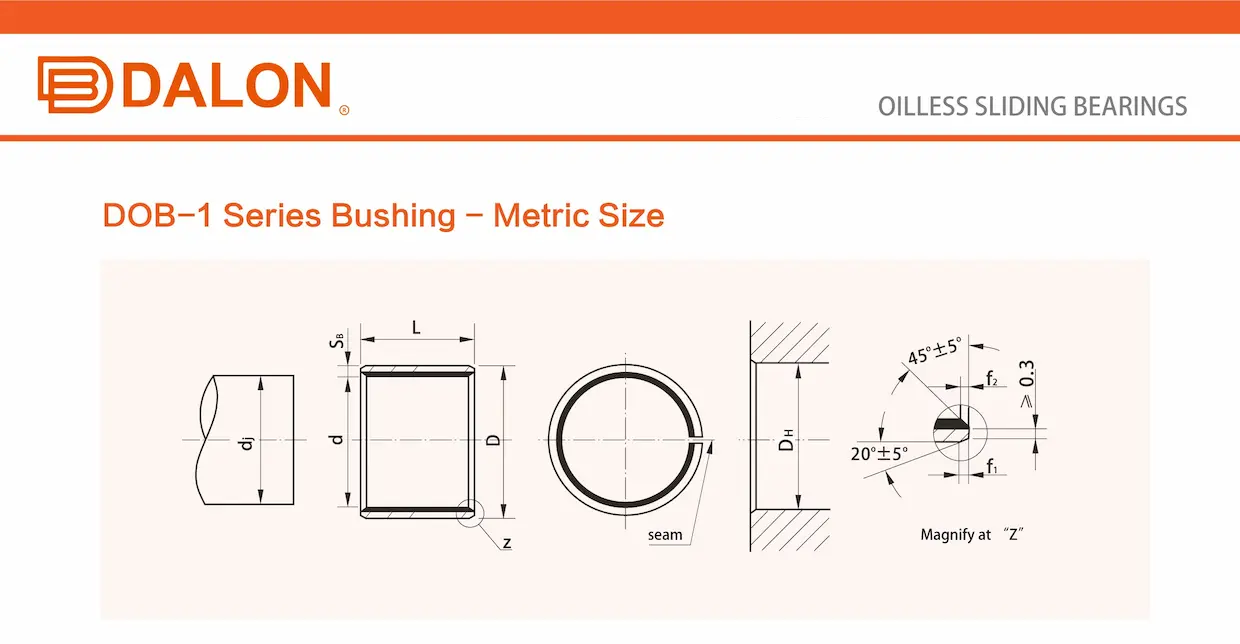

| Type | FLANGE BUSHING |

| Working Temperature | From -200°C to + 280°C |

| Product Code | DOB-1F |

| Density (g/cmÂł) | 7.5 |

| HS Code | 8483300090 |

| Hardness | >220 |

| Static Load (Mpa) | 250 |

| Max Speed (m/s) | 2.5 |

| Max PV (dry) | 1.8 |

| I.D.(d) | 30 |

| I.D. (d1) | |

| O.D. (D) | 34 |

| O.D. (D1) | |

| Length (L) | 2 |

| Flange Dia. (fd) | 42 |

| Flange Thickness (fl) | 26 |

| General Tolerance | F7 r7 js13 |

| Weight(ref)/Gram | 0.00 |

| Minimum Order Qty | 40KGS |

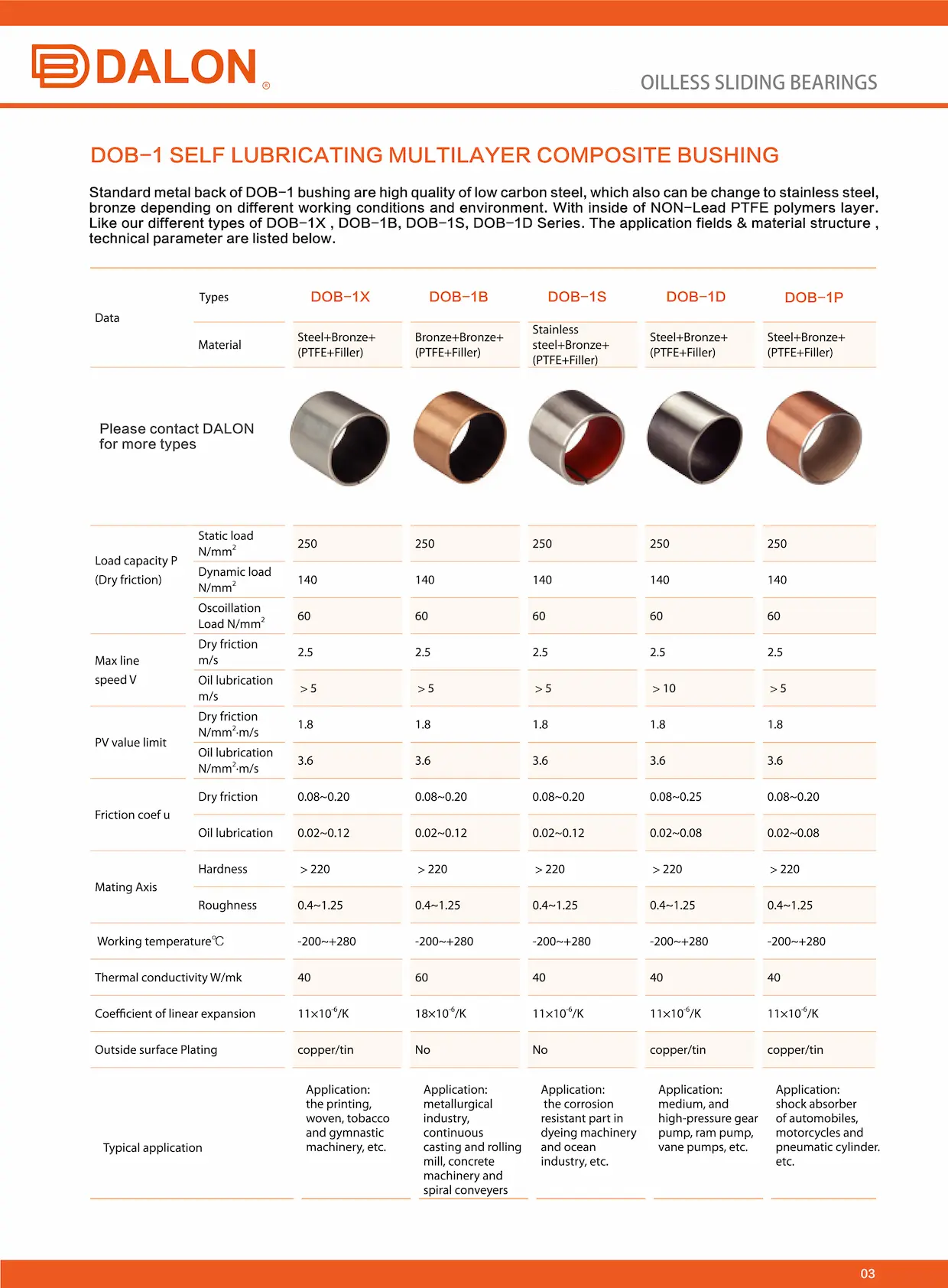

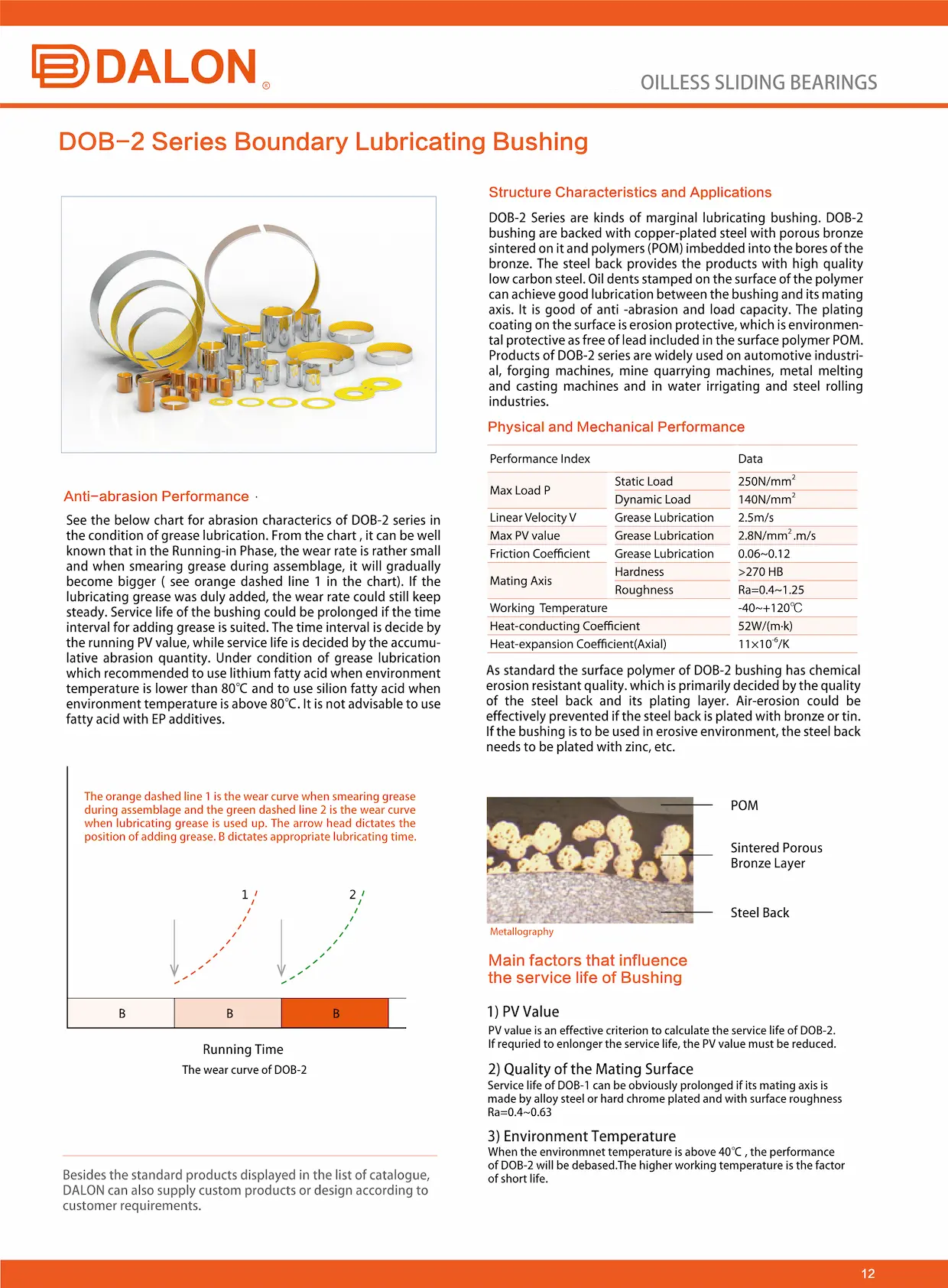

DALON’s Bi-Metal Flanged Bushing 30×34×42×2×26 is engineered to deliver superior performance in high-load, low-speed rotational or oscillating applications. This bushing consists of a steel backing for mechanical strength and a sintered bronze layer impregnated with lubricant for excellent wear resistance and friction reduction. The integrated flange ensures precise axial alignment and simplifies mounting in housings.

Inner Diameter (ID): 30 mm

Outer Diameter (OD): 34 mm

Flange Outer Diameter: 42 mm

Flange Thickness: 2 mm

Total Length: 26 mm

Compliant with DALON’s specification rules, this bi-metal sleeve with flange balances structural strength and low-friction operation—making it ideal for demanding mechanical setups.

Structure: Steel + Sintered Bronze composite (bi-metal)

Lubrication: Embedded with solid lubricant; maintenance-free

Working Temp Range: –40°C to +280°C

Load Capacity: Suitable for heavy-duty static or dynamic radial/axial loads

Installation: Flanged design supports secure axial retention

Durability: Excellent anti-seizure, anti-fatigue, and thermal conductivity properties

Manufacturing Standard: ISO 9001:2015 certified production

Agricultural equipment (pivots, lifts)

Construction machinery joints

Hydraulic cylinders and loader pivots

Automotive suspension joints and powertrain systems

Machine tool linear guides

Industrial presses and rotating levers

As an experienced supplier of self-lubricated and composite bushings, DALON provides:

Precision Customization: We tailor ID, OD, length, flange dimensions, grooves, and coatings to meet your exact specifications

Global OEM Service: Trusted by mechanical engineers across Europe, North America, and Asia

Delivery Commitment:

Existing mold: Delivery in 30 days

Custom design: 35–40 days including mold making

Material Expertise: From bronze and iron to bi-metal and polymer composites

Engineering Support: CAD verification, tolerance consultation, and design recommendations included

Q1: What is a bi-metal bushing used for?

It combines high mechanical strength from the steel backing with low friction and wear resistance from the bronze layer—ideal for load-bearing, slow-movement joints.

Q2: Does this bushing require lubrication?

No external lubrication is needed. The bronze layer is pre-impregnated with oil or solid lubricants.

Q3: Can I use this bearing in wet or dirty environments?

Yes, bi-metal bushings are rugged and suitable for dirty, dusty, or corrosive environments. Additional coatings are available on request.

Q4: Is this suitable for high-temperature applications?

Yes, the bushing operates effectively up to 280°C depending on lubrication type and load.

Q5: What are the minimum quantities for custom orders?

Minimum order quantities vary based on design and size. Please contact DALON for specifics.

Q6: What do people also ask about bi-metal bushings?

What are bi-metal bearings made of? – Typically steel backing + sintered bronze layer.

Are bi-metal bushings better than bronze? – Bi-metal designs offer higher load capacity while maintaining low friction.

Can bi-metal bushings be used in rotating shafts? – Yes, especially under heavy load and slow rotation conditions.

The self-lubricating properties of SLIDING FLANGE BUSHING 30X34X42X2X26 make them ideal for numerous applications, including:

SLIDING FLANGE BUSHING 30X34X42X2X26 are designed for environments where traditional lubrication is impractical or impossible. They offer outstanding performance, durability, and cost savings, making them the preferred choice for various industries. Experience the reliability and efficiency of SLIDING FLANGE BUSHING 30X34X42X2X26, tailored to meet the demands of your specific applications.

Our professional team is ready to assist with your inquiry for this Bi-Metal Flanged Sleeve Bearing – 30×34×42×2×26.

Contact UsAll our products are manufactured according to ISO 9001 standards.

View CertificatesWe offer free design services and custom manufacturing for your specific needs.

We provide worldwide shipping for all our products with reliable delivery times.